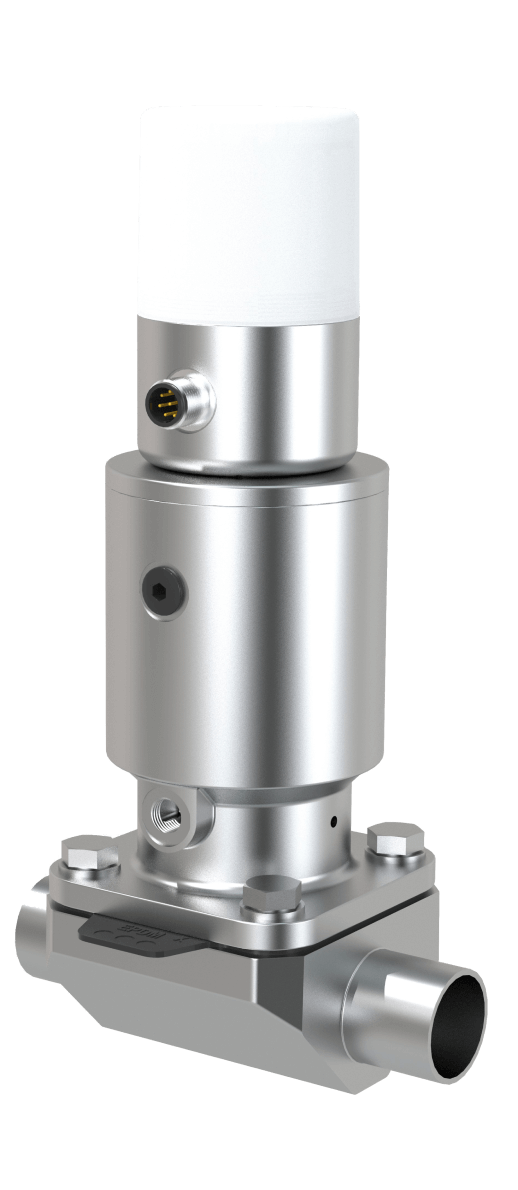

How Diaphragm Valves Work

Diaphragm valves are used in sterile and aseptic processes where the purity of the product is the top priority, such as the manufacture of pharmaceutical products as well as in biotechnology, but also in the cosmetics and food industries.

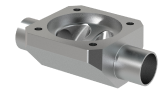

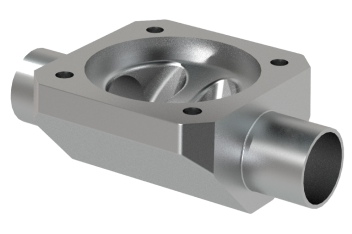

SISTO-C diaphragm valves are characterized by the fact that they are self-draining and free of deadleg.

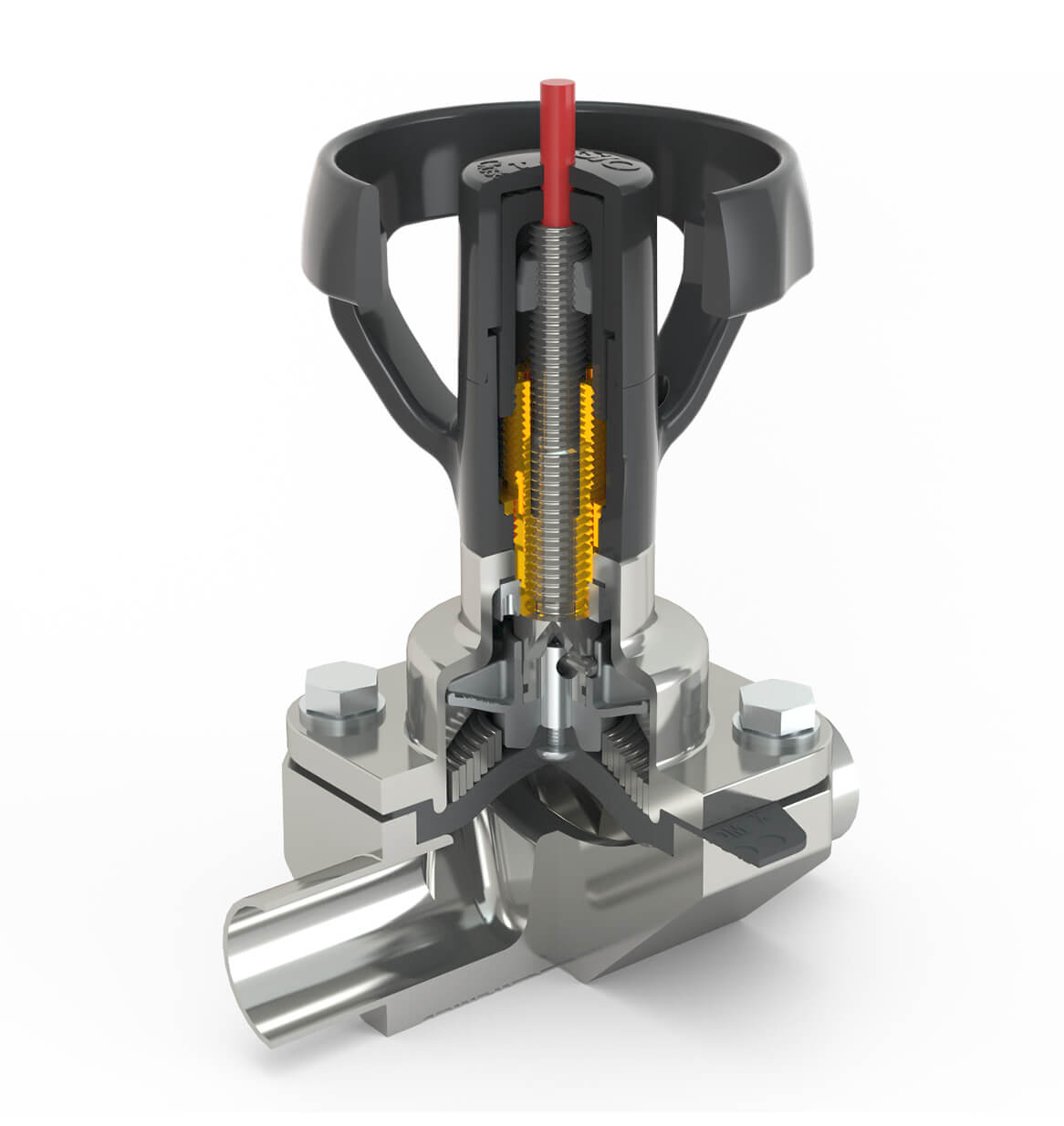

The diaphragm seals hermetically and isolates the actuator from the fluid chamber. As a result, the actuating components do not come into contact with the media. This means

- no risk of contamination of the media by the drive components,

- there is no risk of corrosion of the components by the media.

This means that the valve can be operated at all times, even after longer periods of inactivity.