Outstanding quality

In almost no other area of production are there higher requirements for the purity of the product than in the production of active pharmaceutical ingredients. Ensuring sterility and avoiding microbial contamination is the primary goal.

The manufacturing processes in the pharmaceutical industry are therefore subject to the strictest system and product quality demands as well as high safety requirements.

Our decades of experience in the development, design and production of diaphragm valves, coupled with our knowledge of the special requirements of sterile process engineering, make SISTO a leading manufacturer of diaphragm valves.

“In order to meet the high demands of sterile applications, all our production steps, from the purchase of raw materials through the various stages of manufacturing to the finished product, are subject to stringent quality controls.”

– Philipp Gaudlitz, Managing Director SISTO Armaturen S.A.

Deep value chain, high flexibility

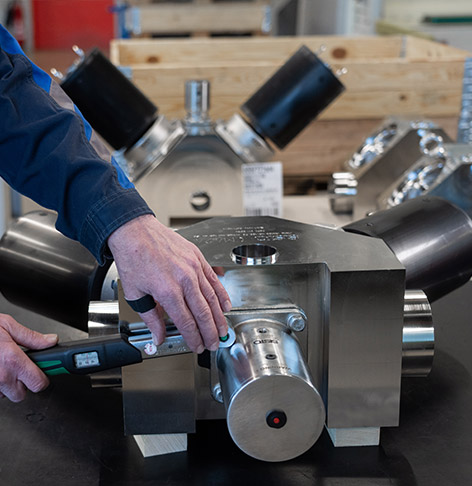

To maintain a consistently high quality level, all quality-impacting production processes are carried out at SISTO’s own factory: From turning and milling with modern 5- to 9-axis machinery to surface machining and electro-polishing. Even the vulcanisation process of diaphragms takes place in-house. Not only does this setup allow an end-to-end quality assurance, it also gives us the flexibility to manufacture customised designs and in small batch sizes.

A wide range of variants comprising simple straight-way valves, welded designs and complex multi-port valve blocks means that SISTO can offer customised solutions for every type of application which comply with relevant standards (e.g. ASME BPE).

In addition, SISTO undergoes constant monitoring by independent testing institutes.

Milling

Milling  Surface finishing

Surface finishing  Visual check

Visual check  Electropolishing

Electropolishing  Cleaning

Cleaning  Cleaning

Cleaning  Laser marking

Laser marking  Tightness test

Tightness test  Assembly

Assembly